CertEase stands out as one of the leading and renowned HACCP certification Consultants in Uganda, offering top-notch HACCP certification services in Uganda & across major cities such as Kampala, Gulu, Lira, Jinja, Mbarara, Mbale, Entebbe and more.

CertEase offers end-to-end HACCP certification consulting services in Uganda which include implementation, documentation, training, audits, and ensuring affordable access to Food Safety Management System certification in Uganda which is valid & recognized worldwide, HACCP compliance in Uganda is vital for organizations involved in food production, distribution, and retail.

Our HACCP services in Uganda help organizations meet the requirements of HACCP standards, enabling businesses to identify and mitigate any physical, biological & chemical food safety hazards effectively.

We cover all aspects of food safety such as risk analysis, setting control points, and limits. Our HACCP consultancy in Uganda make sure that your business archives & maintains the highest standards of food safety compliance, positioning you as a leader in the competitive food industry.

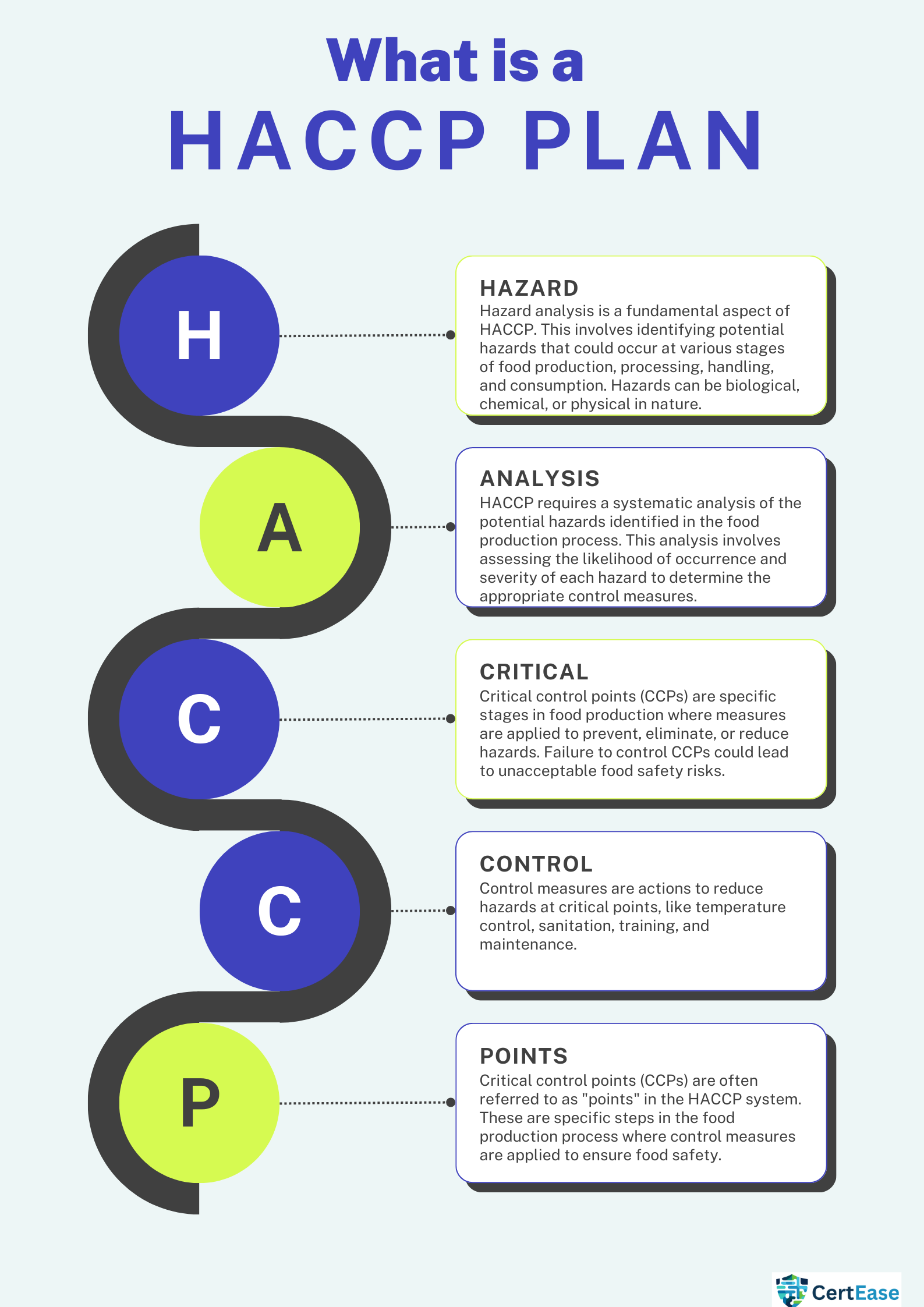

HACCP, also known as Hazard analysis and critical control points is a globally recognized standard for food safety that helps in a systematic way of identifying, evaluating, and controlling biological, chemical, and physical hazards in all stages of the food cycle starting from raw material production, procurement and handling, preparation processes including manufacturing, packaging, distribution and consumption of the finished food products.

The main aim of HACCP is to identify, control & prevent hazards in the entire food production chain. Apart from food, HACCP is also applicable in some of the cosmetics and pharmaceutical industries.

Implementing HACCP standards to your organization helps protect consumer health, and contamination of food, prevents foodborne illnesses or diseases, and maintains consumer confidence in the quality and safety of the brand. This is given prime importance in the food industry.

Hazard Analysis and Critical Control Points in Uganda is essential for industries involved in food production, processing, manufacturing, distribution, and handling. Below is the list of industries who need HACCP certification in Uganda

Overall, any type of industry that is involved in the production, processing, handling, storage, transportation, or distribution of food-related products can benefit from HACCP certification to ensure food safety and compliance with HACCP requirements in Uganda.

The cost of HACCP attestation in Uganda can vary depending on several factors such as the location of the company, nature of business, size, complexity of the organization, scope of certification, number of products, departments operating in the organization, and the chosen certification body. Generally, the cost includes expenses related to the below activities:

1. Initial assessment and gap analysis

2. Training (Awareness & Internal auditor)

3. Assistance in documentation & review

4. Internal audit charges

5. HACCP Auditing fee

6. Certification & surveillance charges

7. Consultant & auditor charges

8. HACCP certification renewal charges

The cost of getting HACCP certification can range from a few hundred to several thousand euros, depending on the above factors. It’s very important for organizations to get quotes from different HACCP certification bodies in Uganda and consider the benefits that can add value to the overall certification when assessing the cost.

Additionally, Organisations should consider getting HACCP certification to their organizations keeping in mind it as an investment since it has many benefits to offer such as improved food safety & overall operations, compliance with regulations, and enhanced brand reputation, which can outweigh the initial expenses.

To apply for HACCP registration in Uganda, below are the listed documents required for HACCP certification in Uganda

1. HACCP Plan: This outlines a detailed plan of the Hazard Analysis and Critical Control Points (HACCP) system specific to your organization’s operations, including hazard identification, control measures, monitoring procedures, corrective actions, and verification activities.

2. Standard Operating Procedures (SOPs): Document all the procedures related to each department & food production and handling which should include sanitation, hygiene, cleaning, pest control, equipment maintenance, and personnel practices.

3. Maintains training records: a detailed record to be maintained of when employees have received HACCP training in Uganda on basic awareness, HACCP principles, food safety practices, and training on their specific roles and responsibilities.

4. Floor plan Layout and Facility Diagrams: Diagrams of the manufacturing site showing the layout of the facility, workflow, and process steps involved in food production, storage, and distribution

5. Supplier Agreements: Sign agreements or contracts with suppliers to make sure that raw materials and ingredients they supply meet specified quality and safety standards.

6. Product Specifications: Specifications for raw materials, ingredients, and finished products, including quality criteria, labelling requirements, and details & shelf-life.

7. Monitoring & Verification Records: Records to be documented with regard to the on-going monitoring of critical control points, as well as verification activities such as product testing, equipment calibration, and internal audits.

8. Corrective Action Procedures: Procedures for addressing diversions or changes from critical limits, non-conformities, and other issues identified during monitoring and verification activities.

9. Recall Plan: A documented plan to be maintained which should include the procedures for managing and taking action on product recalls, including communication with interested parties, customers, regulatory authorities, and the public.

10. Application Form for certification: Application form to be submitted with the details of company name, address, scope & other information & other paperwork required by the certification body for initiating the HACCP certification process in Uganda.

Along with the above documents the organization also needs to submit the following list of documents to apply for the certification – Company trade license, food license, Organisation chart, company sales or purchase order sample, and company address proof.

The above-mentioned documents help demonstrate the organization’s commitment to food safety and compliance with HACCP principles, helping to streamline the certification process. It’s essential to work closely and seek guidance with your certification body to ensure that you provide all necessary documentation and meet their specific requirements.

The HACCP certification in Uganda is typically valid for 3 years. During this 3 years validity period, organizations are required to undergo surveillance audits & renew the certificate each year to ensure on-going compliance with HACCP principles and standards.

These surveillance audits may be conducted annually by the certification body or an accredited third-party auditor, It’s essential for organizations to stay updated on changes to HACCP standards and regulatory requirements to maintain certification validity.

Failing to comply with HACCP certification requirements or in addressing non-conformities found during audits can result in suspension or revocation of the certification.

Regular internal audits and continuous improvement efforts should be given importance by the organization to ensure on-going compliance and maintain HACCP certification & keep it valid. After the completion of 3rd year, the organization must re-apply for HACCP certification in Uganda.

1. Create a project plan & conduct gap assessment & work on findings

2. Provide necessary training to employees & process heads on basic awareness & on how to conduct internal audits

3. End-to-end HACCP Documentation creation

4. Documentation review & corrections

5. Internal audit

6. Closure of observations found in internal audit

7. Management review meeting

8. Apply for an external audit with the certification body

9. Closure of observations found in external audit

10. Final certification

ISO 22000:2018 (Food safety management system): ISO 22000 certification in Uganda specifies requirements for a food safety management system that can be applied by any organization in the food chain, from farm to fork.

FSSC 22000 (Food Safety System Certification): FSSC 22000 certification in Uganda is a scheme for food safety management systems that integrates ISO 22000 and additional requirements recognized by the Global Food Safety Initiative (GFSI).

GMP (Good Manufacturing Practices): GMP certification in Uganda outlines the basic principles and procedures to make sure those products are consistently produced and controlled according to quality standards that are important to ensure the quality and safety of food products.

BRCGS (British Retail Consortium Global Standards): BRCGS certification in Uganda provides a framework for food safety management systems, with a focus on product safety, legality, and quality.

1. Improved Food Safety & Overall Quality: HACCP food safety in Uganda ensures that all kinds of hazards are identified, controlled, and prevented, leading to the production of safer food products for consumers.

2. Enhanced customer trust & Brand Reputation: HACCP-certified companies in Uganda indicate commitment to food safety and the quality food they produce, enhancing brand reputation and consumer trust in the safety of products they consume which also encourages repeat business.

3. Streamlined manufacturing process & overall operations: Developing & Implementing the HACCP plan in Uganda helps organizations in optimizing operations making the production process more streamlined and efficient which will help in the reduction of wastage as well.

4. Increased access to market: HACCP accreditation in Uganda is often considered as a prerequisite for doing business with retailers, suppliers, and customers who require assurance of food safety standards. Hence, having a HACCP certificate can help you get more business reach & worldwide market access.

5. Continuous Improvement: Since HACCP guidelines in Uganda require regular internal audits, surveillance audits, and monitoring and maintaining of documents, it develops a culture of continuous improvement and ensures on-going compliance with food safety standards within the organization which helps maintain stability in everyday operations.

6. Improved Hazard & Risk Management: Implementing HACCP principles in Uganda enables businesses to proactively identify and mitigate food safety risks & Hazards, reducing the contamination of the food, the likelihood of foodborne illnesses, and product recalls.

7. Cultivating a safe work culture: Providing HACCP training in Uganda to the employees can promote a safe and responsible work culture. It allows them to take proactive steps in identifying and preventing potential hazards in the process.

8. Cost savings: Implementing a HACCP system in Uganda will help businesses streamline their existing process & practices which will help in the reduction of waste, and product recalls, and avoid any fines or penalties with regard to non-compliance with food safety regulations. This can help in saving costs over time.

9. Legal & Regulatory compliance: HACCP food certification in Uganda demonstrates compliance with regulatory requirements and helps food businesses & other establishments meet legal obligations & requirements related to food safety.

The seven principles of Hazard Analysis and Critical Control Points (HACCP) are as follows:

Principle 1. Conduct Hazard Analysis for entire your processes: Identify, analyse & evaluate potential biological, chemical, microbiological, and physical hazards in the food production process & provide preventive measures for each hazard.

Principle 2. Determine the critical control points (CCPs): Identify the points in the system where control measures need to be applied to keep the product safe and free from any health hazards to prevent, eliminate, or reduce hazards to acceptable levels.

Principle 3. Establish Critical Limits: Establish critical limits for each CCP, each CCP must be assigned with minimum and maximum allowable limit values to ensure food safety.

Principle 4. Establish Monitoring Procedures: Develop a monitoring procedures process to regularly observe measure & maintain CCPs to ensure they are within critical limits so that food safety compliance is consistently maintained.

Principle 5. Establish Corrective Actions: define corrective actions to be taken when monitoring indicates that a CCP is not within critical limits, establish a set of definite corrective actions that will bring the concerned parameter to safe levels including identifying the cause of the deviation and taking steps to prevent recurrence.

Principle 6. Establish Verification Procedures: Establish procedures to verify that the HACCP system is working effectively, including reviewing records, conducting audits, and testing samples. This will help organizations understand if the food safety plan is working as expected.

Principle 7. Establish Record-Keeping and Documentation: All food safety documents & files related to the HACCP system should be maintained properly which should include records & files documenting the HACCP plan, hazard analysis, CCPs, critical limits, monitoring results, corrective actions, verification activities, and any modifications to the plan.

For organizations to receive HACCP food safety certification in Uganda, it is very necessary that you meet certain criteria and specific requirements set by the standard.

Although the HACCP requirements are the same worldwide, they will vary depending on the type of food business you are into. Let’s take an example, if you are looking to get seafood HACCP verification in Uganda, you may need to meet specific requirements that differ slightly from someone who is getting a food truck HACCP certified in Uganda.

Hence, before applying for HACCP accreditation in Uganda for your organization, it is recommended that you completely understand the requirements of the standard based on the seven principles of HACCP.

1. HACCP Plan & execution: Develop and implement a HACCP plan tailored to your specific operations, products, and hazards. The plan should include the following activities – Conducting hazard analysis, Determining critical control points (CCPs), establishing of critical limits, Establishing monitoring procedures, corrective actions, verification procedures, and record-keeping protocols.

2. Training: HACCP consultants should ensure that the employees & process heads who are involved in the development, implementation, and maintenance of the HACCP system are given necessary training on HACCP principles, procedures, and best practices to, maintain regular compliance.

3. Documentation: Develop & Maintain documentation of the HACCP system, which should include the HACCP plan, hazard analysis, CCP monitoring records, corrective action reports, verification records, internal audit reports, and employee training records.

4. Internal Audits: conducting internal audits regularly are integral part of maintaining HACCP compliance, evaluating the effectiveness & continuous improvement of the HACCP system, and identifying areas for improvement & to make necessary adjustments to procedures based on audit findings. Internal audits are to be conducted at least once a year.

5. External Audit & certification: Schedule for an external audit with a HACCP certification body in Uganda by a recognized accreditation organization. During the audit, the auditor will assess your HACCP system’s compliance with HACCP principles and regulatory requirements clearing the audit will result in final certification

6. Maintaining Certification & continuous improvement: After the final certificate is received it is important to maintain it by continuing to adhere to the requirements of HACCP principles by conducting regular internal audits, and going through in periodic surveillance audits conducted by the certification body.

The time it takes to obtain an HACCP certificate online in Uganda can vary depending on several factors, including the complexity of your food production processes & the readiness of your organization to implement HACCP principles, and the efficiency of your certification process. Generally, the timeline for HACCP certification can range from 2-6 months or more.

Implementing Hazard Analysis Critical Control Points in Uganda is very important for companies to ensure food safety standards within the organization and comply with HACCP certification requirements in Uganda. Food safety risks and hazards will always be a problem in food-related businesses.

Hence, Implementing the HACCP plan into the system can help food companies such as food processing plants and other food-related businesses eliminate food-borne diseases and food contamination from scratch, so it is necessary for organizations to make use of such a plan, or implement other food safely related standards into their facility, to produce hazard free foods to protect their customers from the severe health effects caused by food-related hazards.

HACCP certification consultants in Uganda play a very important role in guiding food-related businesses through the implementation and maintenance of HACCP systems.

Their guidance & expertise ensure organizations meet & comply with food safety regulations, identify potential hazards, and develop effective control measures, ultimately helping improve the overall operations of the facility & enhancing the reputation of businesses by producing hazard-free foods.

Roles & responsibilities of HACCP consulting firm in Uganda: How to get the right HACCP consulting services in Uganda?

1. Planning, Assessment, Implementation: Firstly a HACCP consultant in Uganda will conduct a detailed assessment of the client’s current food safety practices, facilities, and processes & develop a project plan with the deliverables of all the activities covered in the entire consultation process, time & resources required for each activity and help in designing and implementing customized HACCP plans tailored to the specific needs and operations of the client practically and efficiently.

2. Conduct Training: Providing comprehensive training programs to educate employees & process heads on HACCP principles, procedures, best practices & their roles & responsibilities to maintain regular compliance with HACCP standards.

3. Documentation assistance and Record-Keeping: Documentation is a crucial aspect is HACCP hazard analysis in Uganda. Our consultants help in the creation and maintenance of detailed documentation required for HACCP compliance which includes hazard analysis, critical control points, monitoring procedures, corrective actions, verification records & record-keeping making it easy for organizations to manage HACCP plan

4. Assistance in audits & Continuous Improvement: assistance in conducting periodic internal audits and inspections to ensure on-going compliance with HACCP standards since Food safety is an on-going process our consultants will monitor and review your HACCP system & its efficiency and provide inputs on areas of improvement and other necessary recommendations to keep you updated with changing regulations or industry standards to stay compliant.

If you are wondering how to get HACCP consultants in Uganda following are the things you need to consider & evaluate to find the right HACCP consulting agency in Uganda, start by defining your needs and researching online for HACCP certification online in Uganda to choose the right experienced professionals. Check their details including past experience with HACCP projects and relevant industry experience.

Look out for referrals & review their projects from trusted sources and client testimonials. Conduct meetings with the consultant to assess their expertise, approach, Scope of Services, and knowledge of Legal and Regulatory requirements to deliver quality service.

Request proposals and negotiate terms, ensuring alignment with your budget and expectations Once selected, monitor progress closely and communicate openly throughout the engagement to ensure successful implementation of HACCP principles and compliance with food safety standards.

The HACCP audit services in Uganda is a thorough assessment conducted on the company’s operations & documentation to ensure food safety and regulatory compliance with HACCP requirements.

The audit is usually conducted from a HACCP certifying agency in Uganda wherein a lead auditor will begin with planning and preparation, where an organization needs to define the scope and objectives. An on-site assessment is then carried out on the product facility, processes, and employee’s practices related to food safety.

The auditor evaluates hazard analysis procedures to identify potential risks and critical control points where measures are applied. Monitoring and verification procedures are scrutinized to ensure control measures are effectively implemented and verified. Corrective actions are assessed for addressing deviations from critical limits.

Documentation related to HACCP such as plans, monitoring records, procedures, policies, and corrective actions is reviewed to check their effectiveness & accuracy. Post external audit, a report is generated which includes details about findings in audit such as non-conformities, and recommendations for improvement.

Organizations must work on those findings verify compliance and monitor progress. Ultimately, the HACCP audit process serves to maintain the integrity of food safety management systems to ensure the production of safe and quality food products.

So if you are wondering who gives HACCP certification in Uganda & how to get HACCP certified in Uganda the simple answer is to find an HACCP consulting & certification agency in Uganda like CertEase. Who takes up the entire responsibility of delivering end-to-end HACCP services economically & efficiently?

With a Proven Track Record & experience of over 10+ years CertEase offers tailored & Customized Solutions for all your food safety consulting, training & certification needs for further details you can drop an inquiry by visiting our official website www.certease.com or reach out to us by writing us a mail on contact@certease.com or by calling us on +91 89517-32524 to get instant response from our HACCP experts in Uganda.

Directly or indirectly improving the organization’s profits in the short/long term in a sustainable manner

Our seasoned professionals bring expertise to every project, ensuring precision and success.

Our dedicated team ensures reliability and prompt solutions around the clock, Count on us for unwavering support.

Our experts bring verified proficiency to address your specific needs. Choose assurance, choose excellence.

Tailored to suit your specific business needs, our services make it effortless for you to obtain high-quality certifications.

Please complete the form below to receive a detailed Cost Estimation.