RoHS certification is a critical aspect for manufacturers and distributors of electrical and electronic equipment (EEE), not only in the European Union but globally due to its widespread adoption and influence on international trade standards. The Restriction of Hazardous Substances (RoHS) Directive initially introduced by the EU in 2002, and its subsequent updates (RoHS 2 in 2011 and RoHS 3 in 2015), aim to limit the use of specific hazardous materials in EEE. These regulations have profound implications for product design, manufacturing processes, and environmental sustainability.

The RoHS directive restricts the use of ten hazardous materials: Lead, Mercury, Cadmium, Hexavalent Chromium, Polybrominated Biphenyls (PBB), Polybrominated Diphenyl Ethers (PBDE), Bis(2-Ethylhexyl) phthalate (DEHP), Butyl benzyl phthalate (BBP), Dibutyl phthalate (DBP), and Diisobutyl phthalate (DIBP). These substances have been identified due to their potential harm to human health and the environment, prompting a global shift towards safer alternatives in EEE production.

Compliance with RoHS is not only a legal requirement for selling EEE in the EU but also a market expectation in many other regions. Several states in the USA, such as California, New Jersey, Illinois, Indiana, Minnesota, and New York, have enacted legislation mirroring or inspired by RoHS standards. These regulations necessitate manufacturers and distributors to ensure their products meet specific maximum concentration values for the restricted substances if they wish to enter these markets.

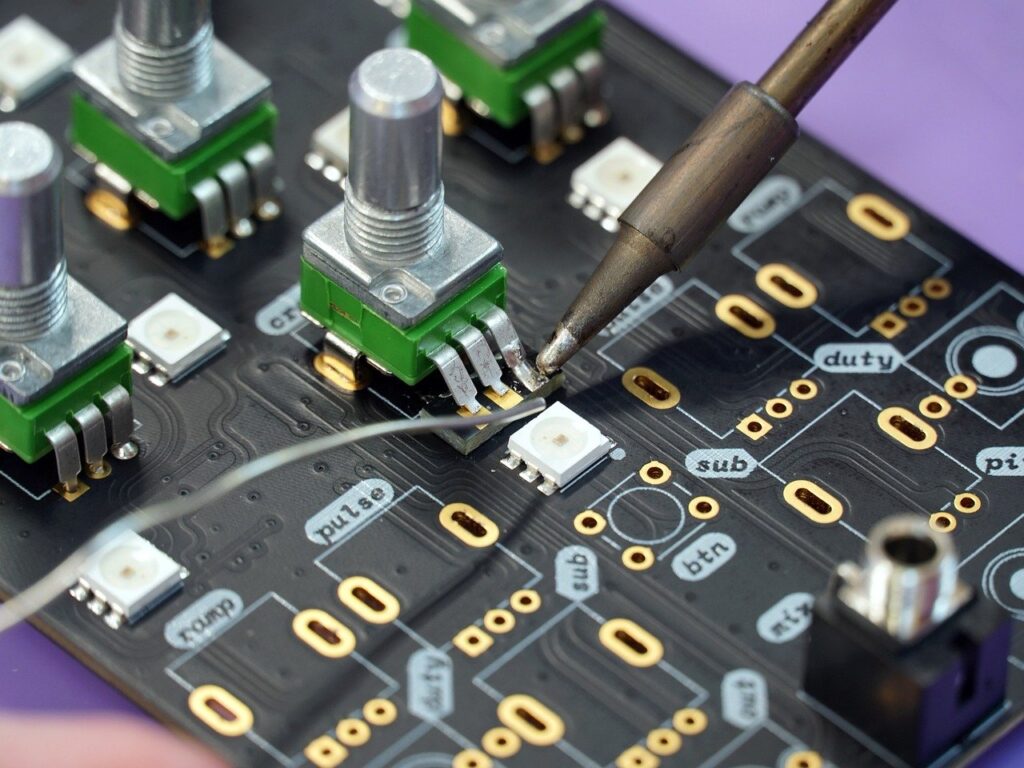

Achieving RoHS certification involves a structured process that includes testing for the ten restricted substances, conducting an on-site process audit, reviewing extensive documentation (such as Bill of Materials, Technical File, and compliance certificates from suppliers), and ultimately, receiving a RoHS Certificate of Compliance upon successful audit completion. This certification asserts that a product complies with the RoHS directive, making it eligible for sale in regulated markets.

RoHS compliance is now integral to the CE marking process for EEE, signifying that a product meets the EU’s safety, health, and environmental requirements. The directive’s scope has expanded over the years to include a broad range of products under its purview, encompassing large and small household appliances, IT and telecommunications equipment, consumer electronics, lighting equipment, electronic and electrical tools, toys, leisure and sports equipment, medical devices, monitoring and control instruments, and automatic dispensers, among others.

The evolution of the RoHS directive reflects the growing global emphasis on environmental protection and consumer safety in the electronics industry. As the directive continues to evolve, with reviews and amendments to address emerging environmental concerns and technological advancements, companies must stay informed and adapt their practices accordingly to ensure compliance and maintain access to key markets.

For businesses involved in the manufacture or distribution of EEE, navigating RoHS compliance is complex but essential for market access, environmental responsibility, and consumer safety. Comprehensive resources, guidelines, and consulting services are available to assist companies in understanding and meeting these regulatory requirements, underscoring the importance of proactive engagement with RoHS compliance strategies.