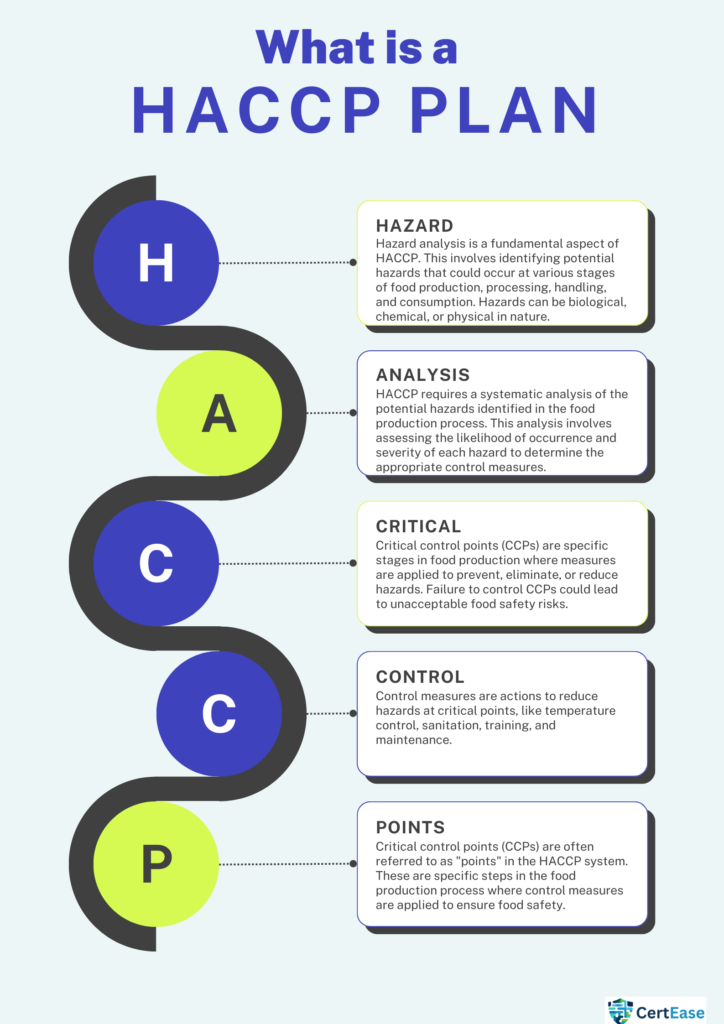

HACCP (Hazard Analysis Critical Control Points) is a comprehensive management system focused on ensuring food safety from production to consumption. It’s recognized internationally and used extensively across the food industry to manage food safety risks by identifying and controlling biological, chemical, and physical hazards. This systematic approach has been embraced globally by government agencies, trade associations, and the food industry due to its effectiveness in preventing food safety hazards.

The origins of HACCP can be traced back to the 1960s, during NASA’s space food program. It was developed to ensure the safety of food for astronauts, applying principles from engineering management to control risks in food production. This innovative approach was first applied by Pillsbury, marking a significant shift towards preventive food safety measures in the industry. Over time, HACCP has evolved, with its principles being refined and adopted across various sectors of the food industry.

The seven principles of HACCP serve as its foundation, guiding the analysis and control of food safety hazards:

- Conduct a hazard analysis to identify potential food safety hazards.

- Identify the critical control points (CCPs) where control can prevent or reduce food safety hazards.

- Establish critical limits for each CCP.

- Set up monitoring procedures for CCPs.

- Determine corrective actions to be taken when monitoring indicates a deviation from an established critical limit.

- Implement procedures to verify that the HACCP system is working as intended.

- Establish record-keeping and documentation procedures.

Implementing a HACCP plan involves preliminary steps like assembling a HACCP team, describing the product, identifying its intended use, constructing a flow diagram of the process, and conducting onsite confirmation of the flow diagram. This groundwork is crucial for a successful HACCP plan, emphasizing the plan’s preventive nature and its role in maintaining food safety.

Moreover, HACCP’s significance extends beyond ensuring food safety; it’s integral to meeting the requirements of modern food safety regulations, such as the FDA’s Food Safety Modernization Act (FSMA). While HACCP plans are specific to each product and process, they provide a robust platform for compliance with global food safety standards and regulations.

The success of a HACCP system hinges on thorough education, training, and the commitment of all employees to uphold food safety standards. Ongoing training and adherence to prerequisite programs like good manufacturing practices (GMPs) and sanitation standard operating procedures (SSOPs) are essential elements of a robust food safety program.

HACCP certification plays a pivotal role in the food industry, offering a “golden ticket” for businesses to demonstrate their dedication to food safety. The certification process, typically conducted by third-party auditing bodies, assesses a company’s food safety management system against HACCP principles. This evaluation includes reviewing documentation, conducting onsite inspections, and interviewing staff to ensure comprehensive compliance with food safety standards.

In conclusion, HACCP represents a critical element in the global effort to ensure food safety. Its development, rooted in the need for high standards of food safety for space exploration, has transformed food safety management across the world. By following the HACCP principles, food industry professionals can significantly reduce the risk of food safety hazards, thereby protecting consumers and enhancing the quality and safety of food products.